- silk screen printing

- peel-off lacquer

- carbon prints with coating thickness ≥ 15 μm

For the various fields of applications, we generally use halogen-free solder resists.

Our classic standard coating is the green XV501 HF produced from the company ”Coates” which is cast on the PCB. For other coatings and colours we use a silk-screen printing method.

| Tolerances for luminous exposure: |

≤ 50 μm |

| Bridges between the SMD-pads depending on the final surface: |

≥ 80 μm |

| Plugging of PCBs with filling print without elevations: |

up to 0.60 mm |

| Colour pallet: |

green (standard)

white, yellow, red, blue,

black (matt and glossy) |

Carbon print: technical options, layout and tolerances

Carbon print: technical options, layout and tolerances

Carbon is used for keyboard contacts, LCD-contacts and contact plugs.

Due to the fact that carbon is applied via silk-screen printing, the precision is closely tied to the copper thickness. All following data are based on a CU-level of approximately 40 µm.

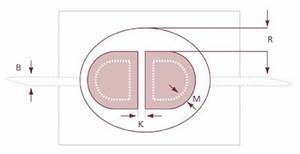

In order to realise the carbon print, the following layout requirements have to be taken into account:

| Layout requirements | |

|---|

| Carbon coating thickness: |

15-30 µm |

| Printing width min. (B): |

≥ 0.30 mm |

| Insulation distance carbon / carbon (K): |

≥ 0.30 mm |

| Insulation distance carbon / copper: |

≥ 0.30 mm |

| Overlapping carbon / copper (M): |

≥ 0.30 mm |

| Distance carbon / solder resist mask (R): |

≥ 0.30 mm |

| Overlapping carbon / solder resist mask: |

≥ 0.40 mm |

| Contour definition of the carbon: |

≤ 0.15 mm |